Innovation

in every cast

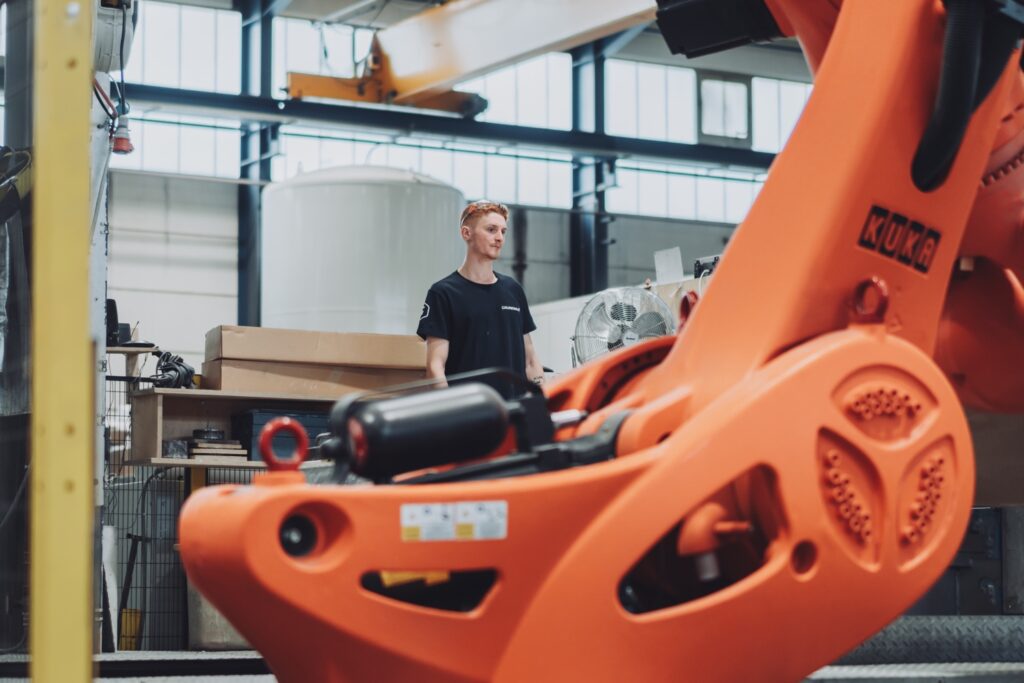

At Grunewald, we combine state-of-the-art technology with precision craftsmanship to produce aluminum and iron sand casting prototypes of the highest quality.

Discover our customized solutions for your projects.

Casting expertise - precision and innovation combined

Grunewald stands for outstanding casting expertise and has been setting standards in the industry for decades.

With our in-depth expertise and state-of-the-art technology, we realize tailor-made casting solutions that meet the highest demands.

From aluminum and iron alloys to advanced 3D sand printing, we combine traditional craftsmanship with innovative processes to turn your visions into reality.

Rapid prototyping

Small and medium-sized series

Aluminum

alloys

Iron

alloys

3D printing

We offer fast and cost-efficient prototype production to realize your innovative ideas quickly and economically.

Our customized casting and moulding processes enable the efficient production of small and medium-sized series, exactly according to your specifications.

Our lightweight and versatile aluminum alloys are perfectly tailored to the growing requirements of modern applications.

Through targeted heat treatment, we can customize mechanical properties such as tensile strength, yield strength or elongation at break.

In addition, different alloys allow the selection of specific properties such as machinability, weldability and corrosion resistance to meet the needs of our customers.

With high-precision iron alloys and state-of-the-art melting technology, we respond flexibly and quickly to your specific requirements.

With our advanced 3D sand printing process, we create highly precise and complex molds that extend conventional modeling methods and enable the production of very complex geometries.

While traditional molds rely on demoldability without undercuts, 3D printing allows the creation of molds with undercuts that are printed once, cast and then destroyed.

This opens up new possibilities in the production of highly complex components.